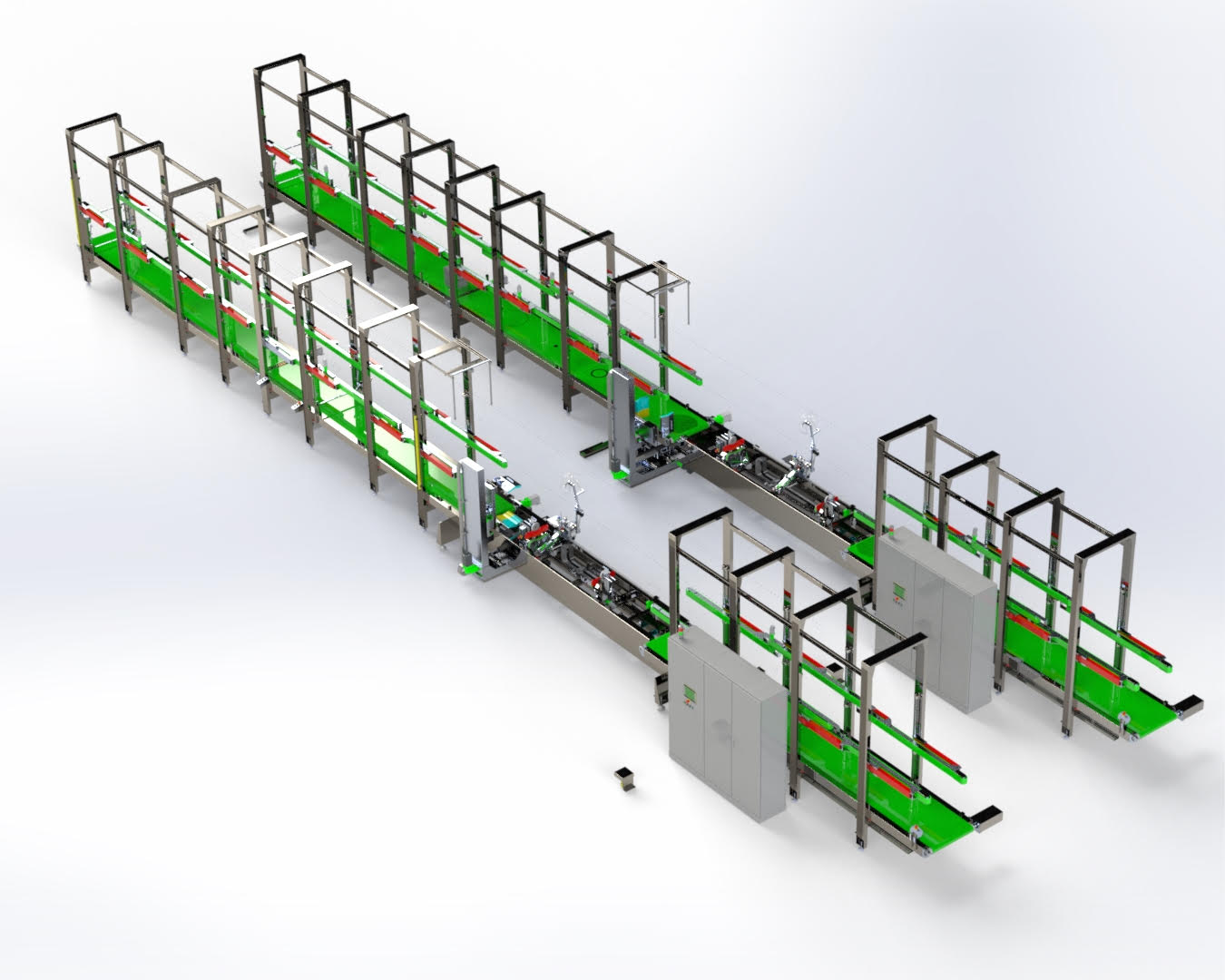

The line is suitable for the processing of cylindrical, conical, oval filters and square shape.

The production line consists of 2 independent lanes, each one composed of electrically connected machines for the exchange of information related to the type of filter to be processed.

Each lane consists of the following machines / units:

– FAST LOADING CONVEYOR BELT, 800 mm wide, 6000 mm length

– SLOW LOADING CONVEYOR BELT 800 mm wide, 6000 mm length

– FILTER CODE READER DEVICE necessary for auto-setting of the machine production

– PICKUP UNIT FOR LOADING / UNLOADING FILTERS FOR THE FILTER BANDING MACHINE with 3 axes (x, y and z), each moved by servomotors

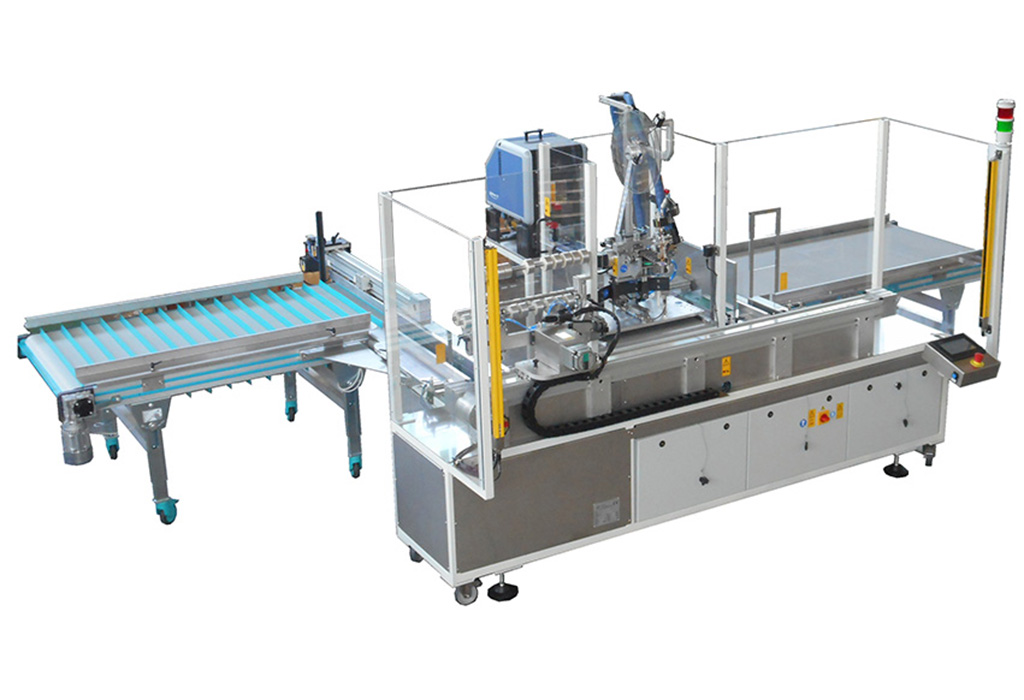

– FILTER BANDING MACHINE WITH AUTO-SETTING

– CONVEYOR BELT FOR UNLOADING, 800 mm wide, 6000 mm length

FSH mod. 519 – Fully Automatic Filters Banding Machine

Technical Data

– dimensions of the filters between D.min. 80 D.max 500

– length min 300 length max 2200

– weight max 20 Kg

The production capacity is about 100 filters per hour (6 straps)

– dimension (cm): 2300 x 390 x H390

– power: 12 Kw, 45A

– air supply: 5 bar

Notes: The data included are not binding

Coupled Cones

Coupled Cones Marron Glacés

Marron Glacés Communion Hosts / Sacramental Bread

Communion Hosts / Sacramental Bread Chocolate Waffle Cone with Sprinkles

Chocolate Waffle Cone with Sprinkles Sugar Wafer Stick

Sugar Wafer Stick Pasteurizer for Ice Cream

Pasteurizer for Ice Cream Cups for Ice Cream

Cups for Ice Cream Shoulder Pads

Shoulder Pads Wadding For Shoulder Pads

Wadding For Shoulder Pads Sleeve Head Rolls

Sleeve Head Rolls Waistband

Waistband Filters

Filters Panel Filters

Panel Filters Bag Filters

Bag Filters Flexible Control Cable

Flexible Control Cable