The machine performs the buttonholes on the wire rope, semi-automatically.

This consists of an iron workbench with dimensions of 150 x 80 x H88 cm in which the following units are applied:

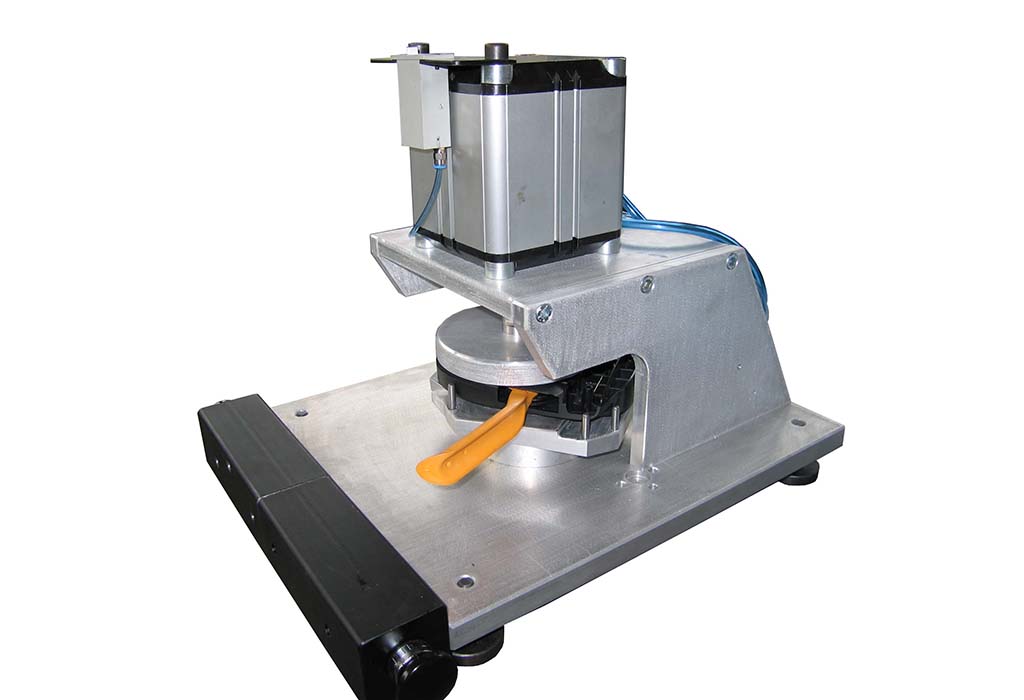

– a pressing unit equipped with an iron structure in which a pneumatic cylinder is applied with a punch and relative support keyed into the cylinder rod for pressing the sleeve, a support surface in which a template is applied for insertion of the sleeve and, possibly, the ring for the buttonhole;

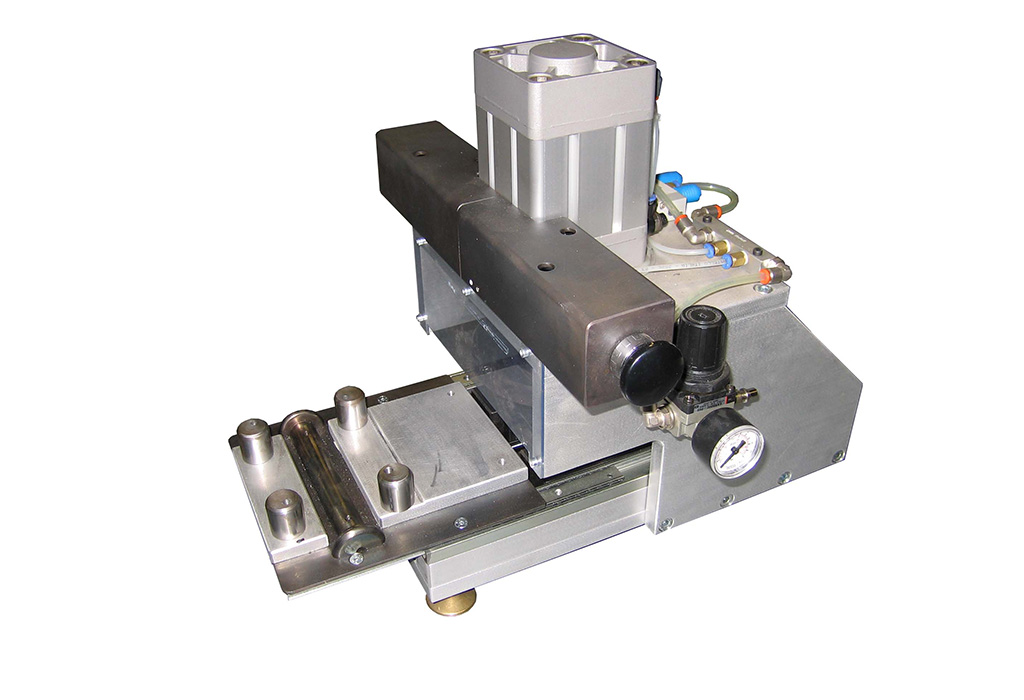

– a rope pulling unit consisting of a vice, operated by a pneumatic cylinder, applied to a guided cylinder: the vice is made to slide by traction of the guided pneumatic cylinder;

– a pneumatic control panel for the management of the work cycle, in which the pressure regulators with manometers for setting the various forces, the group of valves and timers are inserted;

– a push-button panel with two-hand control and emergency button for stopping the work cycle.

ML-01 – Machine Eyelet Forming For Wire

Technical Data

– dimensions 150 x 80 x H160 cm

– weight 100 Kg

– pneumatic supply 5 bar

The operator inserts the sleeve and, if necessary, also the ring for the slot, in the respective seats of the template, then inserts the rope in the various passages, such as the vice, the sleeve and the ring for the buttonhole, and finally presses the two-hand control to start the work cycle.

Notes: The data included are not binding

Coupled Cones

Coupled Cones Marron Glacés

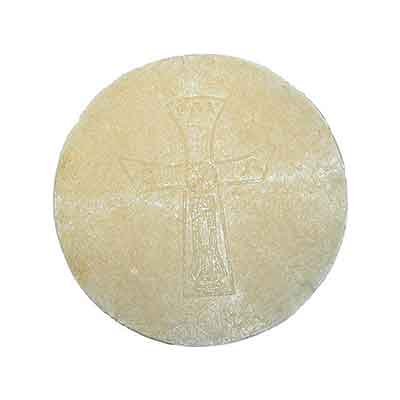

Marron Glacés Communion Hosts / Sacramental Bread

Communion Hosts / Sacramental Bread Chocolate Waffle Cone with Sprinkles

Chocolate Waffle Cone with Sprinkles Sugar Wafer Stick

Sugar Wafer Stick Pasteurizer for Ice Cream

Pasteurizer for Ice Cream Cups for Ice Cream

Cups for Ice Cream Shoulder Pads

Shoulder Pads Wadding For Shoulder Pads

Wadding For Shoulder Pads Sleeve Head Rolls

Sleeve Head Rolls Waistband

Waistband Filters

Filters Panel Filters

Panel Filters Bag Filters

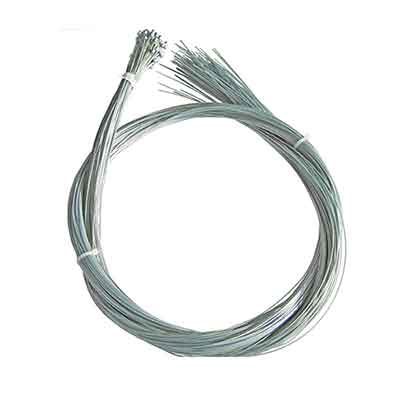

Bag Filters Flexible Control Cable

Flexible Control Cable