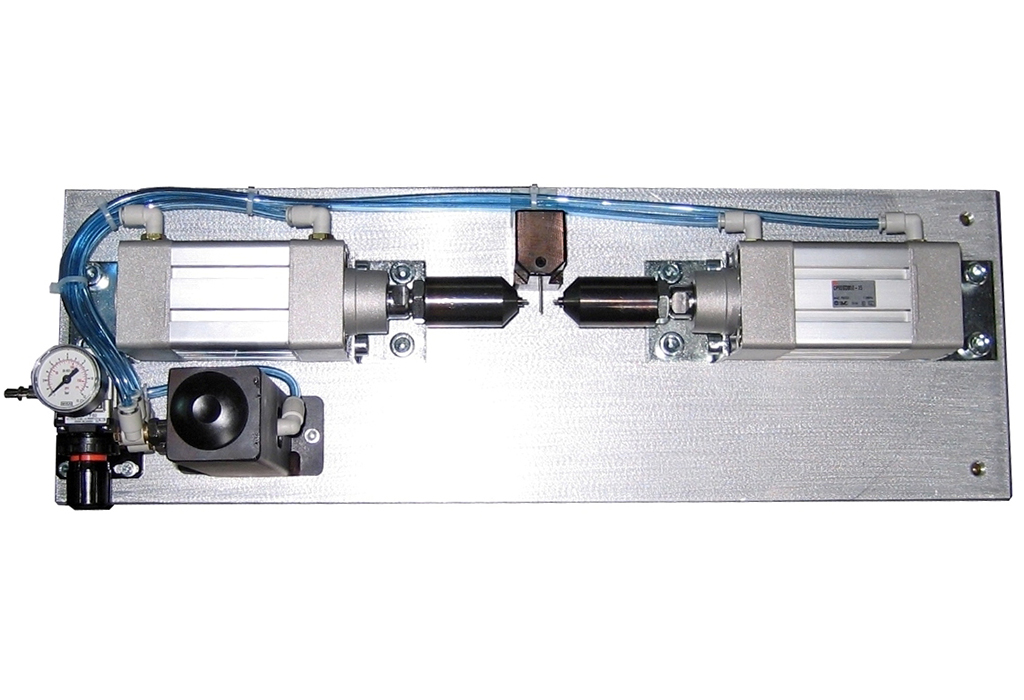

The machine cuts and stamps different sheath diameters to the desired length.

This consists of an iron structure in which the following units are applied:

– a support with unwinding unit to guide the sheath up to the straightening unit

– a SHEATH STRAIGHTENING UNIT located near the 2 stamping machines

– a sheath length measuring system with tachometer wheel

– 2 STAMPING MACHINES each operated by a pneumatic cylinder

– a SHEATH DRIVING GROUP consisting of a pair of drive wheels under pressure with each other

– a CUTTING GROUP consisting of a cutting-off machine with cutting disc

– a pneumatic vice for locking the sheath during the cutting phase

– a warehouse with automatic unloading for the collection of the cut pieces

– an electric control panel with operator panel

MCP-1 – Machine For Marking And Sheath Cutting

Technical Data

– the equipment takes about 5 sec. to carry out the work cycle.

– dimensions: cm. 10,000 x 100 x H180

– 5 bar pneumatic supply

– 400VAC electrical supply

The operator, after having inserted the sheath through the various passages and having set the various data on the operator panel, starts the automatic cycle; periodically, he has the task of removing the cut pieces from the collection tank of the unloading warehouse.

Notes: The data included are not binding

Coupled Cones

Coupled Cones Marron Glacés

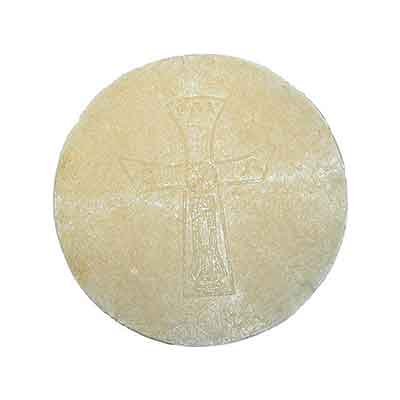

Marron Glacés Communion Hosts / Sacramental Bread

Communion Hosts / Sacramental Bread Chocolate Waffle Cone with Sprinkles

Chocolate Waffle Cone with Sprinkles Sugar Wafer Stick

Sugar Wafer Stick Pasteurizer for Ice Cream

Pasteurizer for Ice Cream Cups for Ice Cream

Cups for Ice Cream Shoulder Pads

Shoulder Pads Wadding For Shoulder Pads

Wadding For Shoulder Pads Sleeve Head Rolls

Sleeve Head Rolls Waistband

Waistband Filters

Filters Panel Filters

Panel Filters Bag Filters

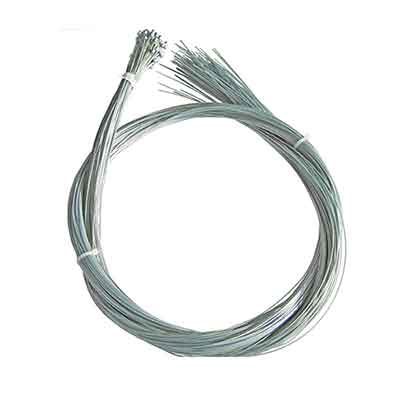

Bag Filters Flexible Control Cable

Flexible Control Cable