Automatic wadding for shoulder pads Series IA mod. 416 is fully automatic; has been designed and manufactured to meet the various demands of production.

Whole machine is managed by an electronic control panel with touch-screen Panel, which can be used to manually control all machine movements.

The operator’s task is to feed the machine loading from No. 1 to No. 5 rolls of cotton (cotton, wool, or cotton + viscose, or polyester, etc …) according to the type of padding that must produce.

Rolls can have a maximum width of 42 cm. Machine is made up of 1 + 4 cutting units which generate layers of padding, equipped by its feeders for transporting wadding tapes, by a system of needle punching to merge the layers of padding with one another, and a rotation disk magazine to collect pieces products.

To change the production from one article to another takes about 5 minutes.

This machine is able to produce the desired shape (e.g. to triangular, oval, trapezoid, etc.); this is conical.

By this machine it is possible to produce wadding with maximum size about cm 37×36.

For the wadding with maximum dimensions cm 37×18, in each of 5 units, it is possible to cut 2 layers at the same time.

IA mod. 416 – Automatic Machinery for Producing Wadding for Shoulder-Pads of 1 to 4 Layers

Technical Data

– the cycle time of approximately 6.5 sec. in 4 units, while for the single to 3 sec.; This value may decrease or increase depending on the size of the pad;

– on the operator panel display displays various information;

– all machine movements can be controlled manually with the operator panel;

– power supply 400V 50 Hz, 2 Kw, 8.5 in.

– Ambient temperature between 10 and 35° C;

– air supply: 5 bar;

– dimension: cm. 412 x 180 x H175;

– weight 1300 Kg

Note: Please note that the data included is not binding.

Coupled Cones

Coupled Cones Marron Glacés

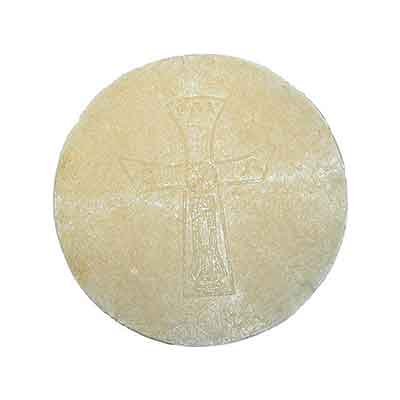

Marron Glacés Communion Hosts / Sacramental Bread

Communion Hosts / Sacramental Bread Chocolate Waffle Cone with Sprinkles

Chocolate Waffle Cone with Sprinkles Sugar Wafer Stick

Sugar Wafer Stick Pasteurizer for Ice Cream

Pasteurizer for Ice Cream Cups for Ice Cream

Cups for Ice Cream Shoulder Pads

Shoulder Pads Wadding For Shoulder Pads

Wadding For Shoulder Pads Sleeve Head Rolls

Sleeve Head Rolls Waistband

Waistband Filters

Filters Panel Filters

Panel Filters Bag Filters

Bag Filters Flexible Control Cable

Flexible Control Cable