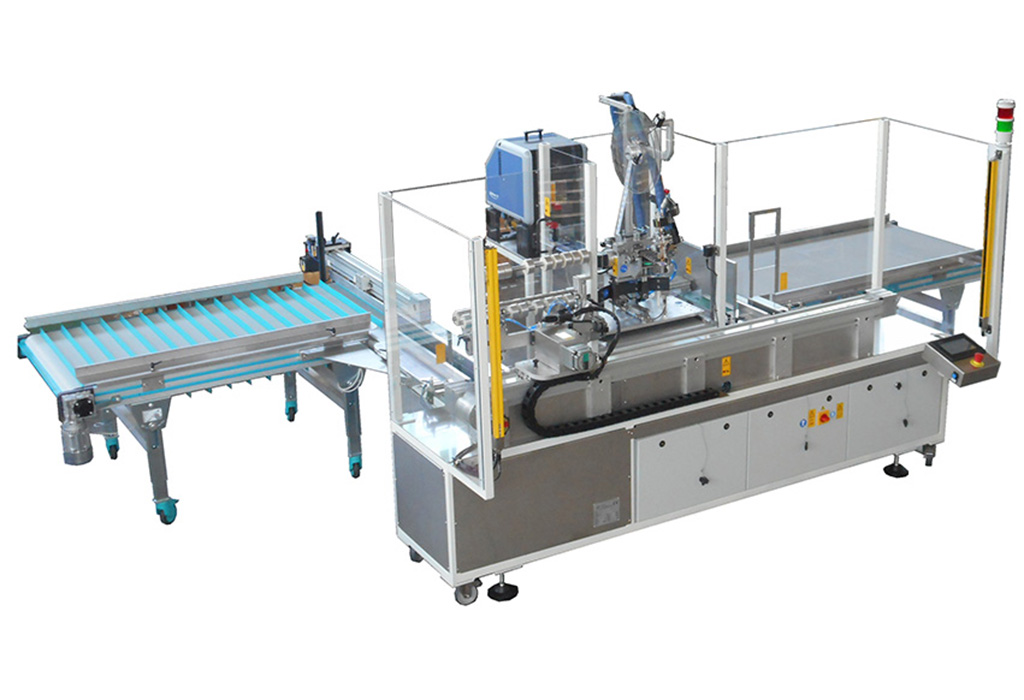

Machine wraps and glues the band on cylindrical filters in various ways, positions and quantities:

– straps

– spiral with a ring at the beginning and one at the end of winding

It is possible to work completely automatically (through the use of loading and unloading magazines), cylindrical filters with a diameter between 40 and 120 mm and a length between 50 and 500 mm.

In semi-automatic mode (manual loading and unloading), it is possible to machine cylindrical filters with a diameter between 115 and 300 mm and a length between 200 and 1100 mm.

In the machine there is a loading magazine consisting of a conveyor belt with legs on wheels of length 1600 mm width 800 mm; this allows the deposit of the filters, up to a maximum of 15 pieces per row, each with a pitch of 130 mm.

For the application of the adhesive, a fuser complete with a heated hose and an applicator with nozzle is used.

The processed filters are automatically collected in a conveyor belt of length 1600 mm width 800 mm with a pair of sides adjustable in width; this allows the deposit of the filters, up to a maximum of 15 pieces per row, each with a step of 130 mm.

At the end of the execution of each filter an electronic system checks the band on the filter

FBM mod. 417 – Fully Automatic Filters Banding Machine

Technical Data

– average production capacity, about 240 pieces / hour

– power supply 400 / 230V 50/60 Hz

– pneumatic supply, 6 bar

– dimensions 502x312x H192

Note: Please note that the data included is not binding.

Coupled Cones

Coupled Cones Marron Glacés

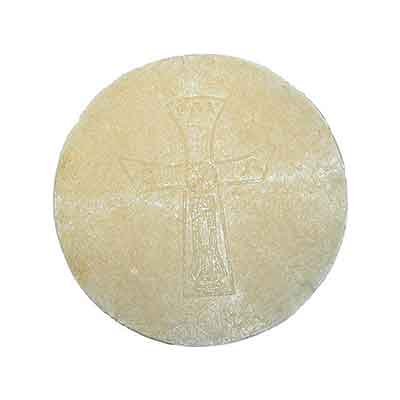

Marron Glacés Communion Hosts / Sacramental Bread

Communion Hosts / Sacramental Bread Chocolate Waffle Cone with Sprinkles

Chocolate Waffle Cone with Sprinkles Sugar Wafer Stick

Sugar Wafer Stick Pasteurizer for Ice Cream

Pasteurizer for Ice Cream Cups for Ice Cream

Cups for Ice Cream Shoulder Pads

Shoulder Pads Wadding For Shoulder Pads

Wadding For Shoulder Pads Sleeve Head Rolls

Sleeve Head Rolls Waistband

Waistband Filters

Filters Panel Filters

Panel Filters Bag Filters

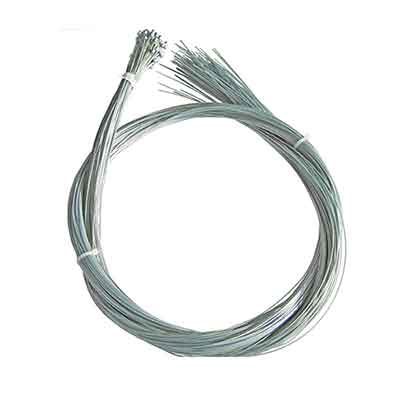

Bag Filters Flexible Control Cable

Flexible Control Cable