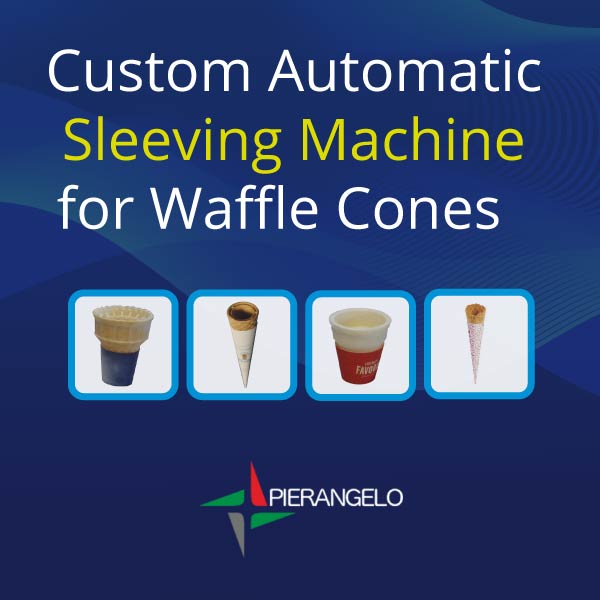

Machine inserts both the sleeves on the waffle cones and on cup cones.

It is consists of the following units:

– a loading plane with 4 lanes (autonomy of about 3,5 min.)

– a loading unit to take and deposit of a series of waffle cones or cup cones above the chain sliding plane

– a dosing unit for depositing the drop of glucose on the waffle cone that acts as a glue with the sleeve

– a unit for inserting the sleeve onto the waffle cone or cup cone, of different sizes and types (this can be done by changing a series of components)

– a conveyor belt for collecting stacks of coupled waffle cones or cup cones

Only one operator is able to follow the machine: he has the task of loading the waffle cones or cup cones and the relevant sleeves onto the machine, and then putting the coupled product into the boxes.

ASM mod. 418 – Automatic Sleeving Machine for Waffle Cones and Cup Cones

Technical Data

– maximum production capacity is around 2880 pieces / hour

– autonomy of the loading plane of the waffle cones or cup cones is about 3.5 min

– autonomy of the loading unit of the sleeves is about 20 min

– Dimensions cm 351 x 225 x H181

Note: Please note that the data included is not binding.

Coupled Cones

Coupled Cones Marron Glacés

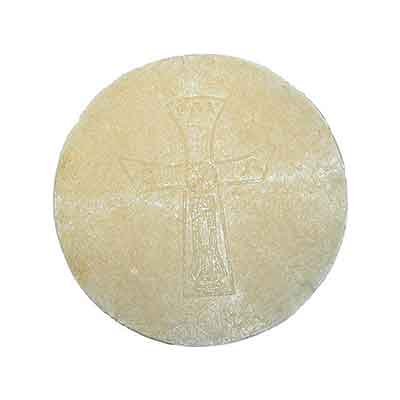

Marron Glacés Communion Hosts / Sacramental Bread

Communion Hosts / Sacramental Bread Chocolate Waffle Cone with Sprinkles

Chocolate Waffle Cone with Sprinkles Sugar Wafer Stick

Sugar Wafer Stick Pasteurizer for Ice Cream

Pasteurizer for Ice Cream Cups for Ice Cream

Cups for Ice Cream Shoulder Pads

Shoulder Pads Wadding For Shoulder Pads

Wadding For Shoulder Pads Sleeve Head Rolls

Sleeve Head Rolls Waistband

Waistband Filters

Filters Panel Filters

Panel Filters Bag Filters

Bag Filters Flexible Control Cable

Flexible Control Cable